Upsizing a Cartier Classic Watch

Background -

I'm not a major "Watch Guy", but have always admired the classic, but industrial look of Cartier's Santos watches. They have a pretty cool history dating back to 1904 when aviation pioneer Alberto Santos-Dumont asked his friend Louis Cartier for a watch he could easily access when flying. At the time, most men used pocket watches (wristwatches were considered feminine and worn mostly by women). The Santos changed that. A bit of history here - Cartier Santos

Cartier's Original Santos Wristwatch - 1910

In 1978 Cartier reintroduced the Santos in 2 shapes- rectangular and octagonal (available in gold/stainless or stainless/stainless). Both shapes became popular standards for many years. At the turn of the century, with large watches becoming the norm, Cartier used the 2004, 100 year anniversary of the Santos to create an upsized XL version of their classic (see photo below).

Cartier Galbee XL (2005-2014) vs older, rectangular Santos (1978-2004)

But... they did not upsize their Octagon (the design I prefer). Being a fabricator, I thought I'd make it myself. And, while at it, add a few (what I consider) improvements. Well, turns out there is a LOT to know about making a "Nice" watch and not many sources of information on how to do so (can you say old-school, secretive industry?). Many parts of the watch required a few iterations to get right. And, it is by no means ready to be a "product". That said, I've been wearing it for a week now, putting it through proper testing (mountain bike rides, trail runs, Symphony concert, fancy art shows, hip San Francisco bar/restaurants) and I must say- it turned out pretty well! In case you were wondering- it is cool as hell to wear your own watch.

Some details -

- With the exception of the Swiss made, 21 jewel ETA 2892-A2 movement (same movement Cartier uses in their upsized rectangular Santos (Galbee XL)) all parts were made by myself and highly skilled employee Trevor Hirschi.

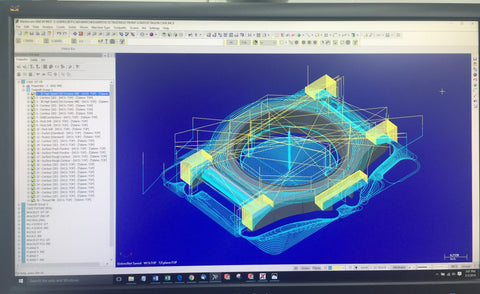

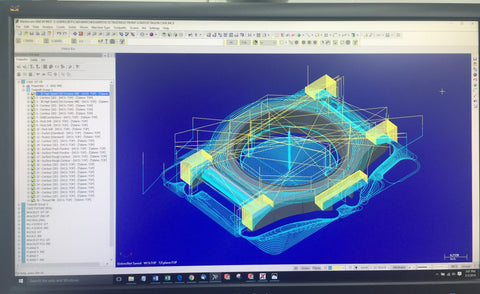

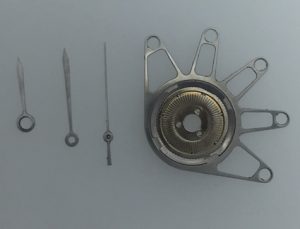

ETA 2892-A movement (without rotor) - 294 different toolpaths had to be programmed to machine all the different parts.

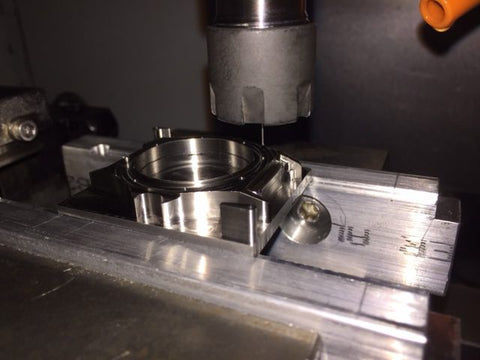

Toolpaths Op1 Case - All parts are machined from 6-4 Titanium billet, not stainless steel.

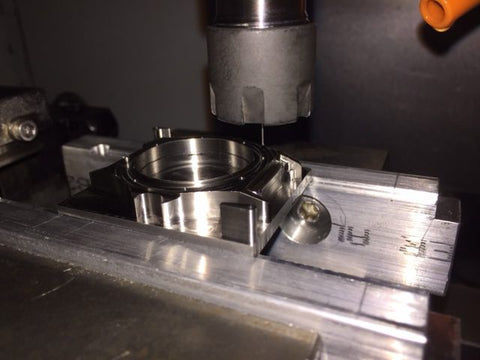

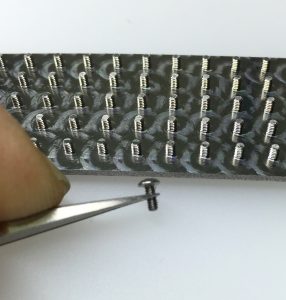

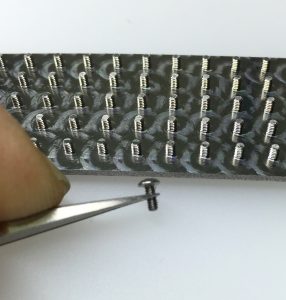

1.2mm helical interpolation threadmilling in case - It always bothered me that Cartier’s bracelet screws are merely cosmetic (they do nothing). I redesigned the bracelet links to be pinless. Screws are now integral to the links’ tongue and groove functionality (see photo below).

-

Its not possible to buy screws in the sizes I needed. So they had to be made.

-

To have the proper bracelet taper, there are six different link widths (makes design and programming challenging).

-

Automatic watch movements (self-winding) are really cool miniature machines. I added an exhibition back so one can literally see “what makes them tick”.

-

My one modification to the ETA movement is I added my own “Rotor” (the automatic pendulum). I machined the bracket from 316 stainless steel, while the weight was 3D printed in wax, then cast in 18K gold. The five screws are also 18K.

- Crown gemstone is a natural blue sapphire. Cartier has unfortunately switched to lower cost Spinel.

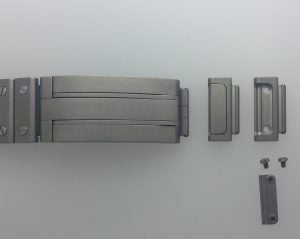

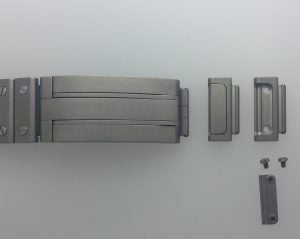

- Bracelet buckle (Deployant) is patterned after my wedding ring clasp and works pretty nicely.

- Watch face was milled from billet 6061 aluminum using a 1/64” (.39mm) endmill.

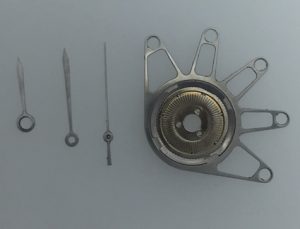

- Watch hands are milled from billet 316 stainless. The Seconds hand is one of the most challenging things I have ever machined (it has a .0098” (.25mm)) bore in the hub.

Conclusions-

I did this project to learn a bit about watchmaking and of course, to make myself a cool watch. A new product was on my mind, but there is so much work in this watch, the price would be very high. And… people that buy very high priced watches are justifiably very particular. Scrutiny takes place under magnification- tiny scratches and surface imperfections are not tolerated. Subtle details like hands shape, size and color are critical. Movements need to be quality in-house or expertly customized. In short- it’s a big decision to make watches for sale and I’ve yet to decide if I will. That all said, my second watch idea is rolling around in my head and will be WAY cooler than this first watch. Stay tuned!

Jeff